When Change Is Looming: What the Weaving Loom Teaches Us About AI’s 5-Year Horizon

- Severin Sorensen

- Aug 7, 2025

- 6 min read

We stand at another inflection point, hearing the steady clack-clack of progress in the distance. Only this time the shuttle moving toward us isn’t made of wood and iron—it’s artificial intelligence. And the “looming” disruption (pun very much intended) will arrive in 5-10 years, not 50.

A 19th-Century Microsimulation

Productivity windfall, human whiplash. Mechanized looms multiplied output 40×, yet they displaced hundreds of thousands of skilled hand-loom weavers and triggered decades of social unrest and wage collapse.

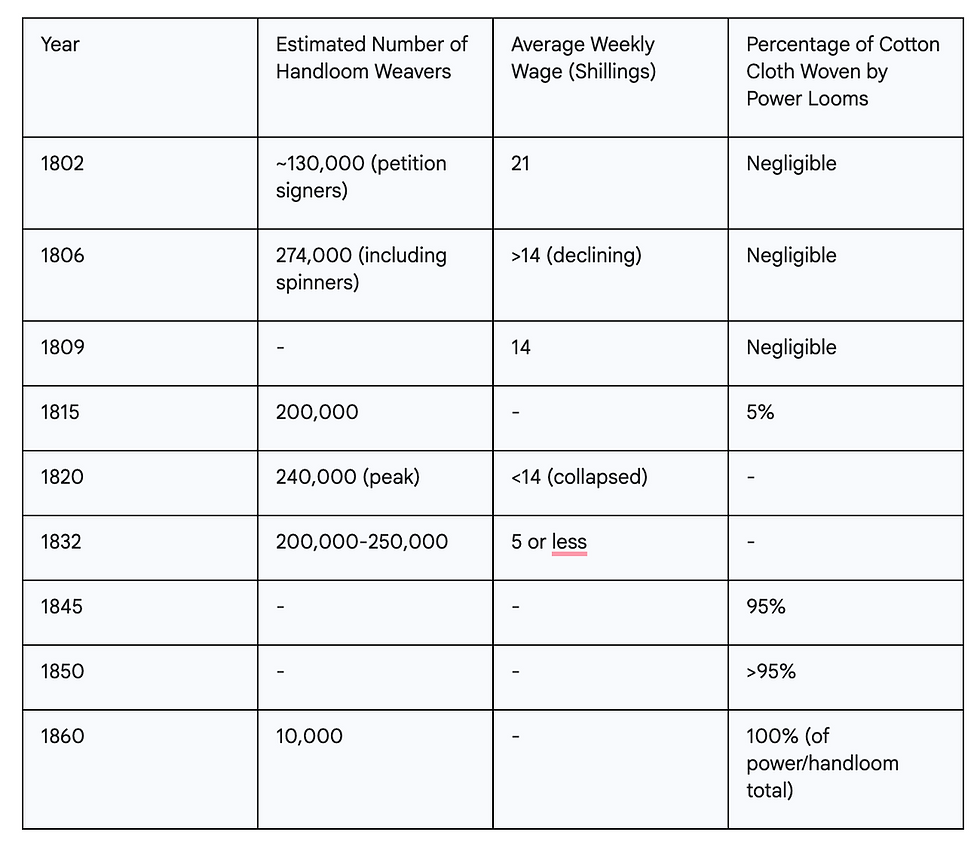

From aristocracy of labour to poverty in a decade. Wages fell from 21 shillings to as little as 5 shillings a week; by 1860 only ~10,000 of the original 240,000 weavers were still plying their craft.

Re-employment was slow, generational, uneven. Most displaced artisans never reclaimed comparable status; true absorption into new jobs took half a century and often skipped a generation.

Skill “hollow-outs” hurt the middle most. Mid-skill crafts faded first, pushing workers either upward into white-collar roles or downward into low-skill factory labor—an early case of labor-market polarization.

Key Weaving Loom Innovations and Their Economic Impact (Industrial Revolution Era)

The sequence of key inventions in the textile industry during this period illustrates a dynamic interplay of challenges and solutions:

John Kay's Flying Shuttle (1733): This invention dramatically speeded up the weaving process by allowing a weaver to pull the weft thread horizontally across the warp with greater ease and speed, enabling the production of wider textiles. It effectively doubled a weaver's output, creating a significant bottleneck in the supply of yarn, as spinning could not keep pace.

James Hargreaves' Spinning Jenny (1764): In response to the yarn shortage, Hargreaves' spinning jenny mechanized spinning, initially allowing a single machine to spin eight threads simultaneously, later improving to 120 threads. This invention significantly increased yarn production, addressing the imbalance created by the flying shuttle.

Richard Arkwright's Water Frame (1769): A further advancement in spinning, the water frame was a water-powered cotton-spinning machine that produced a much finer and stronger yarn than the spinning jenny, further enhancing spinning efficiency and quality.

Samuel Crompton's Spinning Mule (1779): Combining the principles of both the spinning jenny and the water frame, the spinning mule produced even finer and more uniform yarn. This complex machine could measure up to 46 meters long and significantly increased the number of available spindles, with some models having up to 1,320 spindles, vastly increasing output.

Edmund Cartwright's Power Loom (1785): This was the pivotal invention for weaving, initially water-powered and later adapted for steam power. The power loom doubled the speed of cloth production. While Cartwright's initial design was not immediately efficient, its theoretical principles were sound and continuously improved by subsequent inventors, laying the groundwork for mechanized weaving.

Eli Whitney's Cotton Gin (1794): This invention mechanized the separation of sticky seeds from cotton fibers, dramatically increasing the productivity of raw cotton processing by a factor of 50. This ensured a vast and affordable supply of raw material for the burgeoning textile mills.

Joseph Marie Jacquard's Loom (1801): Utilizing punched cards to control intricate patterns, the Jacquard loom was a revolutionary machine that allowed for very complicated designs to be woven. Its use of punched cards is widely recognized as a precursor to modern computer science.

Richard Roberts' Loom (1822): Roberts invented the first cast-iron, steam-powered loom. Using iron instead of wood, as in Cartwright's earlier design, prevented warping and maintained constant yarn tension, significantly improving the machine's efficiency and reliability.

A Sea Change in Employment

So what happened to employment in this industry as a result, and how long did it take for workers to migrate and retrain for new roles in other sectors?

The advent of the mechanized loom, while a triumph of engineering, unleashed a powerful force of "creative destruction" that fundamentally reshaped the social and economic fabric of the time. This process, as described by Schumpeter, involves new innovations displacing older industries, leading to significant disruption and hardship for those whose livelihoods are rendered obsolete.

Handloom Weaver Employment and Wage Trends (UK, 1800-1850)

The displacement of handloom weavers and other traditional artisans during the Industrial Revolution was a significant social challenge, but it also catalyzed the emergence of new industries and job roles, albeit over a protracted period of adaptation.

Despite the initial short-term job losses, the Industrial Revolution ultimately created new types of jobs that did not exist previously.23 The overall industrial labor force expanded dramatically. In the United States, for example, the number of people involved in industrial labor soared from 3.5 million in 1870 to 14.2 million by 1910.24 This growth was driven by new and expanding sectors:

Iron and Steel Workers: This sector saw an immense increase, growing by over 1,200% between 1870 and 1910, reaching 326,000 workers.

Fabricators of Goods from Metals: By 1910, this group constituted almost 12% of the industrial labor force, experiencing a 437% growth over forty years.

Machinists: Essential for manufacturing the new industrial machines, the number of machinists rose from 55,000 in 1870 to 283,000 by 1900.

Transportation: The burgeoning industrial economy required a vast transportation network. By the end of the 19th century, over half a million men were needed just to drive horses and wagons delivering goods in congested city streets, and railroad track crews also expanded significantly.

Other Factory Work: Tens of thousands of migrants, such as French Canadians, moved to New England to work in textile, shoe, or paper mills, indicating a shift in the labor pool for these industries.

Clerical and Administrative Roles: As industrial capitalism grew in complexity, there was a rapid increase in white-collar jobs, including administrative and clerical workers, reflecting the expanding organizational needs of large-scale enterprises.

This period witnessed a fundamental change in the nature of work, characterized by a declining demand for "middle-skilled" labor, such as artisanal craftsmen, in manufacturing.

This led to a "hollowing out" of the skill distribution, where workers were often reallocated into comparatively less-skilled occupations. This structural change meant that the newly created jobs were not simply replacements for the old ones but often required different, sometimes fewer, skills or offered lower status than the artisanal roles they supplanted.

And it took 50+ years to redeploy labor displaced in the loom industry. And the transition for displaced workers was fraught with challenges. Many struggled due to the obsolescence of their occupation-specific human capital—skills and knowledge tailored to their old jobs that were difficult to transfer to emerging sectors. Older workers, in particular, were more vulnerable to this technological displacement. They were more likely to switch to unskilled physical labor, facing a higher loss of their accumulated skills and having a shorter period to retrain for new roles. This highlights a significant social cost of skill obsolescence, demonstrating how human capital, once a source of stability, could become a liability in a rapidly changing technological landscape, disproportionately affecting experienced workers and often leading to a step down the occupational-skill ladder.

Even for those who found new employment, the economic impact was substantial. Displaced workers often experienced significant earnings losses upon re-employment, even in expanding job markets. Studies indicate that workers with more than twenty years of tenure in their previous jobs could see average earnings losses of over 30%.

Furthermore, the rapid urbanization that accompanied industrial growth led to overcrowded cities with poor living conditions, including a lack of clean water, overflowing sewage, and inadequate nutrition, which made life particularly difficult for the new working class and their families.

Which brings me to the point of this article; we don't have the luxury of 50 years to redeploy labor in the age of AI. We don’t have fifty years this time. AI’s productivity shock will unfold within one business cycle, not two generations.

If we wait for the labor market to “self-correct,” we’ll repeat the loom’s pain at warp speed.

Why This History Matters Now

Compression of time. The loom’s upheaval unfolded over 50 years; AI’s comparable productivity leap is expected inside a single business cycle.

Same pattern, faster cadence. Creative destruction still starts with efficiency gains, skyrocketing demand, and—shortly thereafter—an employment crunch among middle-skill roles.

Retraining race. Victorian society had decades to react (and still struggled). We have maybe 60 months to reskill at scale.

Policy echoes. Loom-era turmoil birthed the Factory Acts and early social-safety nets. Today’s debates on UBI, portable benefits, and lifelong learning echo those 19th-century first drafts.

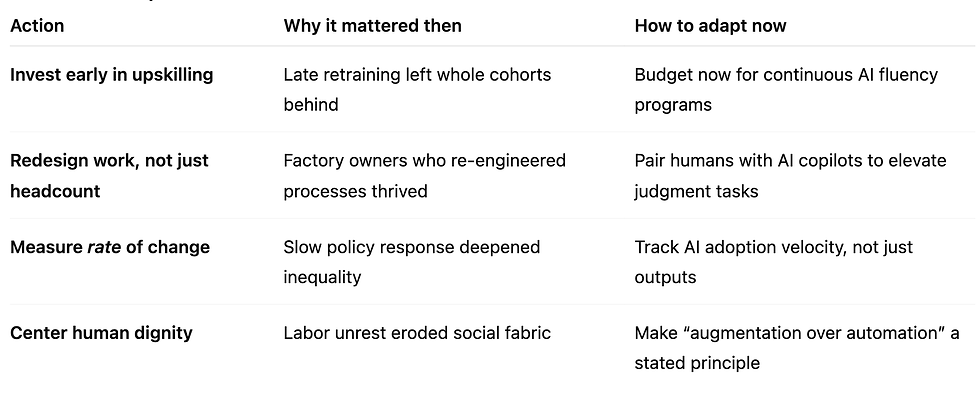

Four Loom-Inspired Actions for Leaders

A Closing Thread

The weaving loom’s story is more than a relic—it’s a high-speed preview of our own future. Ignore its lessons, and the fabric of work may tear; heed them, and we can weave a richer, fairer tapestry.

In Part 2 I’ll lay out a rapid-response blueprint to modernize job-training systems before the next shuttle completes its circuit. Act now, or brace for avoidable turbulence—disruption, chaos, and market upheaval. Buckle up.

The shuttle is already in motion. Are you ready for what’s looming?

Copyright © 2025 by Arete Coach™ LLC. All rights reserved.

Comments